Alloy:7075

Width: 500mm - 2300mm

Thickness: 0.2mm - 350mm

Port of Loading: Qingdao

Certificated: ISO9001:2015 and AS9100

7075 aircraft aluminum is one of the highest strength aluminum alloys available, on par with several types of steel. Its strength-to-weight ratio is excellent, and it is ideally used for highly stressed parts. Because of its strength threshold, 7075 aluminum is often used for those parts of the airplane aluminum that experience high-stress levels like the wing spar. Available in the alclad form to provide corrosion resistance with the over-all high strength being only moderately affected.

Aluminium Alloy 7075 offers the highest strength of the common screw machine alloys. The superior stress corrosion resistance of T173 and T7351 tempers makes aluminum alloy 7075 a logical replacement for 2024, 2014 and 2017 aluminum in many of the most critical applications. The T6 and T651 tempers have fair machinability. Alloy 7075 is heavily utilized by the aircraft and ordnance industries because of its superior strength.

Chemical composition of 7075 Aircraft Aluminum

Chemical Composition Limits | |||||||||||

Weight% | Al | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other Each | Others Total |

7075 min | Rem | - | - | 1.2 | - | 2.1 | 0.18 | 5.1 | - | - | - |

7075 max | Rem | 0.40 | 0.50 | 2.0 | 0.30 | 2.9 | 0.28 | 6.1 | 0.20 | 0.05 | 0.15 |

Specification of 7075 Aircraft Grade Aluminium

Material | Temper | Size (") | Tensile Strength (ksi) | Yield Strength (ksi) | Elongation in 2" % |

Alloy 7075 Bar | T651 | - | 77 | 66 | 7 |

Alloy 7075 Bar | T7351 | <4" | 68 | 56 | 10 |

Alloy 7075 Bar | T73511 | <0.25 | 68 | 58 | 7 |

Alloy 7075 Bar | T73511 | 0.25 - 1.5 | 70 | 61 | 8 |

Alloy 7075 Bar | T73511 | 1.5 - 3.0 | 69 | 59 | 8 |

Alloy 7075 Bar | T6511 | <0.25 | 78 | 70 | 7 |

Alloy 7075 Bar | T6511 | 0.25 - 0.5 | 81 | 73 | 7 |

Alloy 7075 Bar | T6511 | 0.5 - 3.0 | 81 | 72 | 7 |

Material | Temper | Thickness (in) | Tensile Strength (ksi) | Yield Strength (ksi) | Elongation % |

Alloy 7075 Sheet | T6 Bare | 0.125 - 0.25 | 78 | 69 | 8 |

Alloy 7075 Sheet | T651 Bare | 0.25 - 0.50 | 78 | 67 | 9 |

Alloy 7075 Sheet | T651 Bare | 0.5 - 1.0 | 78 | 68 | 7 |

Alloy 7075 Sheet | T6 Clad | 0.188 - 0.25 | 75 | 64 | 8 |

Alloy 7075 Sheet | T651 Clad | 0.25 - 0.50 | 75 | 65 | 9 |

Alloy 7075 Sheet | T651 Clad | 0.5 - 1.00 | 78 | 68 | 7 |

Characteristic | English | Metric |

Nominal Density (68° F / 20°C) | 0.101 lbs./ in ³ | 2.80 Mg/m³ |

Melting Range | 990° F - 1175° F | 532°C - 635 °C |

Specific Heat (212 °F / 100°C | 0.23 BTU/lb - °F | 960 J/kg-°K |

Characteristics of 7075 Aircraft Grade Aluminum

• Poor formability or workability

• Poor weldability

• Fair machinability

• Average resistance to corrosion

• Heat-treated

• High strength

• Commonly used in the aerospace industry

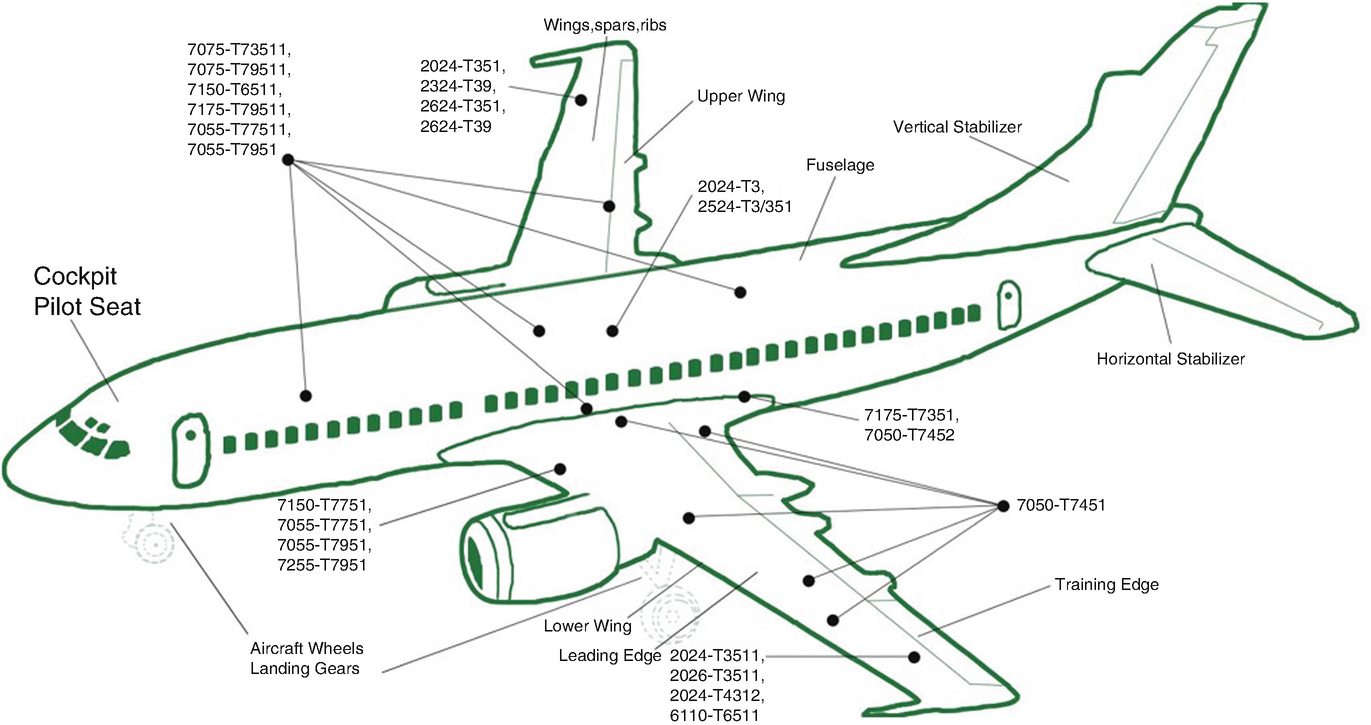

Applications of 7075 Aircraft Aluminium

Due to its high strength and good resistance to stress-corrosion cracking, aluminum 7075 is commonly used for:

• Structural parts that are highly stressed

• Fittings for aircraft

• Shafts and gears

• Components of missiles

• Additional parts for the aircraft and aerospace industry

Related Application