Alloy:7050

Width: 500mm - 2300mm

Thickness: 0.2mm - 350mm

Port of Loading: Qingdao

Certificated: ISO9001:2015 and AS9100

7050 Alloy increased the content of zinc and copper, increased the ratio of zinc to magnesium, and replaced chromium with zirconium as a grain refiner, and greatly reduced the content of iron and silicon. These improvements and over aging treatment make the aircraft grade aluminum 7050 type alloys have good comprehensive properties such as good toughness, high fatigue strength and good corrosion resistance at high strength level. Another outstanding advantage of type 7050 Alloy is good hardenability, especially for the manufacture of heavy section parts such as forgings.

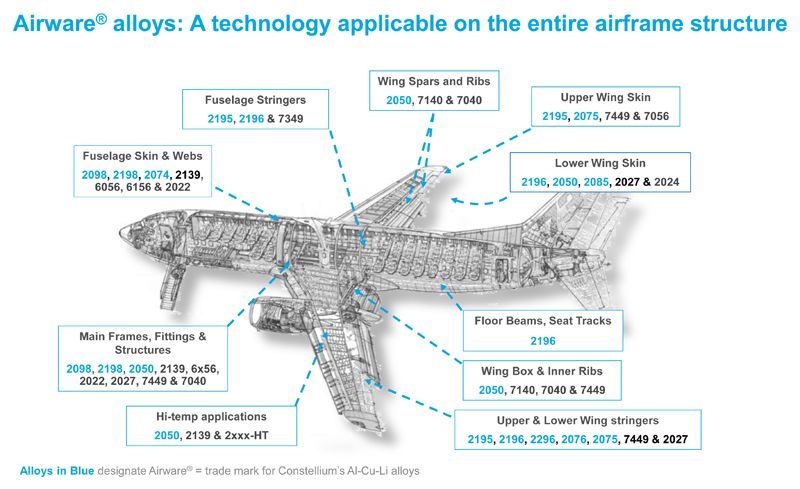

The 7050 aluminum alloy plate profile forgings is mainly used for aircraft structure parts, such as fuselage frames, partitions, wing panels, wing beams, wing ribs, landing gear support parts and rivets, which require high light, high stress corrosion and peeling corrosion resistance and good fracture toughness. When the temperature rises, the strength of the 7050 aluminium alloy will be reduced, and the long-term use temperature can not exceed 125ºC.

The force components of different temper materials were used for different use conditions: T76 temper General requirements for the structure exfoliation corrosion resistance and high strength; T74 temper for high strength and anti stress corrosion structure, especially the structure of a thick section; the T73 temper is mainly used for rivet wire of high strength, corrosion resistance.

7050 aluminum alloy plate profile forgings has good comprehensive performance, the main supply temper is T7651 thick plate, T7451 thick plate and T7452 forgings. Because of the 7050 Alloy temper variety, application technology is mature, so it is widely used in the manufacture of the fuselage frame and bulkhead, wing skin, extrusion reinforcing rod, stringers and ribs, forging parts, gear supporting components, such as rivets, 7050 aluminum alloy plate profile forgings is currently the most widely used of the 7000 series aluminum alloy.

7050 aluminum Chemical Composition

Cu | Mg | Mn | Fe | Si | Zn | Ti | Cr | Zr | Other | Al |

2.0~2.6 | 1.9~2.6 | 0.1 | 0.15 | 0.12 | 5.7~6.7 | 0.06 | 0.04 | 0.08~0.15 | 0.15 | Remainder |

7050 A7050 EN AW-7050 A97022 Aluminum specification

Alloy Series | Alloy | Tempe | Thickness (MM) | Width (MM) | Length (MM) |

7series | 7050 | T351,T451,T7651,T7451 | 4~12 | 1000~2600 | 2000-24000 |

7series | 7050 | 12~260 | 1000~3800 | 2000~38000 |

7050 A7050 EN AW-7050 Aerospace aluminum Product characters:

1: High strength,

2: High ductility,

3 : High damage tolerance,

4: High performance aircraft plate,

The application of Aluminum plate 7050 T7651 alloy in aerospace

Item | Alloy | Temper | Application |

1 | 7050 | T7651,T7451 | fuselage ring and frame of aerospace |

Related Application